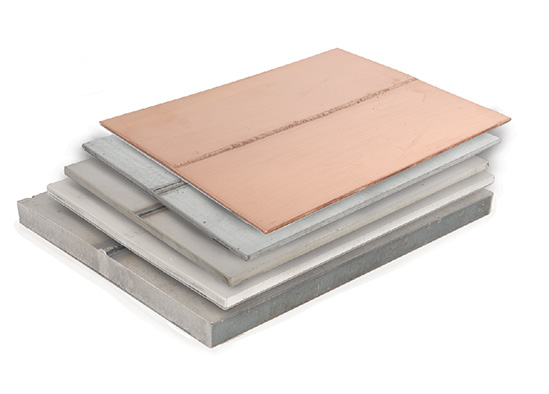

LightWELD Material & Thickness Welding Range

Thick, thin, reflective and dissimilar metal welding without wire that is difficult or impossible with traditional methods, plus weld materials with different electrical conductiv.

- High-speed welding across a wide range of materials and thickness

- Low heat input for minimal part distortion or deformation

- Built-in factory presets for all materials and thickness

| Material | LightWELD XR | LightWELD 1500 LightWELD XC |

|---|---|---|

| Stainless Steel | up to 6.35 mm | up to 4 mm |

| Galvanized Steel | up to 6.35 mm | up to 4 mm |

| Mild Steel | up to 6.35 mm | up to 4 mm |

| Aluminum 3 & 5 Series | up to 6.35 mm | up to 4 mm |

| Aluminum 6 Series | up to 3 mm | - |

| Nickel Alloys | up to 5 mm | - |

| Titanium | up to 5 mm | - |

| Copper | up to 2 mm | - |

LightWELD Pre-Weld Cleaning

- LightWELD XC and LightWELD XR provide pre-weld cleaning for stronger, higher-quality welds.

- Any contaminants can enter the weld pool and compromise weld integrity

- Pulsed cleaning power up to 2500 W peak power evaporates undesired surface elements

- Fast and effective removal of contaminants such as oxides, rust, paint, oil, or grease from surface without the use of chemicals or abrasisves

- Up to 15 mm of adjustable cleaning width with one pass

LightWELD Post-Weld Cleaning

LightWELD XC and LightWELD XR provide post-weld cleaning improves visual finishes

- Post-weld cleaning removes soot, debris, or any sign of localized heating

- Dramatically reduce time, cost and scrap

- Create visually appealling welds while eliminating need for post-grinding

- Up to 15 mm of adjustable cleanning width in one pass

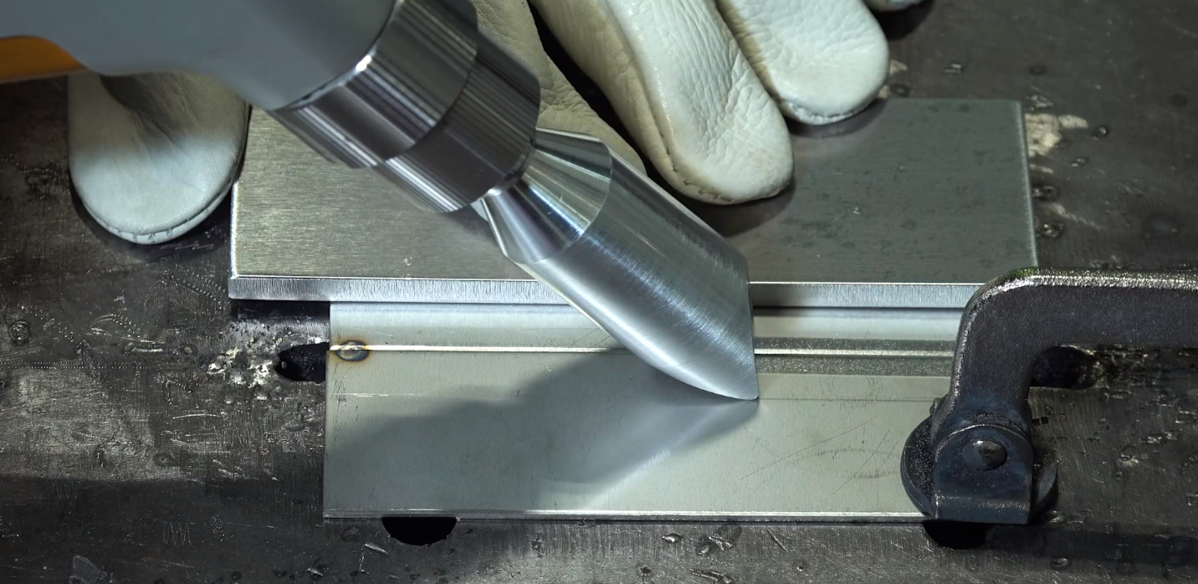

LightWELD offers Welding & Cleaning in a Single System

LightWELD XC and LightWELD XR can switch from welding to cleaning in just seconds

- Specially designed welding and cleaning nozzle tips for any joint configuration.

- Increased productivity using single system for multiple fabrication processes

- Simply loosen the collet and insert a welding or cleaning nozzle, select the appropriate mode and the system is ready to clean or weld